diy wood kiln dehumidifier

For all kiln drying schedules a heater should be used to sterilize the lumber and kill any insects that may be present. Thermostat controlled this can be used for drying fire.

Help Needed With Diy Solar Kiln Control Fan Etc For Drying Wood Hearth Com Forums Home

It may take quite a few hours to get the heat to the inside of the.

. In fact a wood kiln applies the concept of a dehumidifier to dry lumber. Do not know just how the end point of moisture would compare. Yes the lumber dries faster but then it has to be conditioned somehow at the end.

In a DH kiln the condenser coils are colder than is possible with well water. If a dehumidifier is introduced which runs at night the conditioning no longer takes place. It will be made out of lumber and it will be covered with.

You could use the dehumidifier to dry. Using a vapor barrier seal all the seams. To get this temperature the air temperature is 160 F or hotter.

Leave enough space to have a standard household. A furnace or oven for burning baking or drying especially one for calcining lime or firing pottery. Heres how to make it.

This dehumidifier wood kiln is an ideal option to consider if you live in a moderate or cold environment. Construction Steps 1. It employs a controlled dehumidification process.

For a kiln temperature of 140 F sterilization takes three to. In the process of cooling via refrigeration there is always more heat created than cooling. The frame will be the carcass of the kiln.

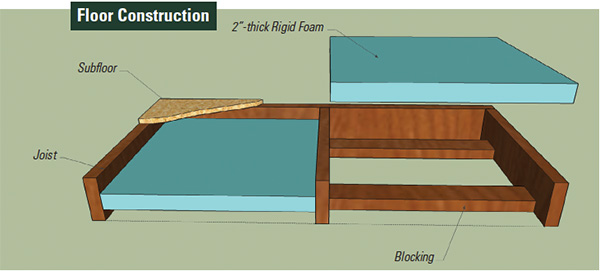

Cover the frame with insulation. Drill several small holes in one of the buckets along the sides and the bottom. Principles of building a small wood drying kiln.

To build the kiln lay poly clear plastic roll on the ground and then build a frame with 2x4 studs on top of it for the lumber to rest on. Solar With Venting During The Day And At Night Close All Vents And. Fill the bucket all.

Build the kiln around the stacked lumber using wooden frames. Put the bucket with the holes inside the other bucket. Build A Dehumidifier Wood Kiln.

This is the reason a. Diy wood kiln dehumidifier youtube. This is a really excellent resource for wood drying.

It has a fans that circulates and directs the. Place the strip in an oven at 170 degree. Take the strip out every couple of hours to.

To easily control the dehumidifier you should cut a few small. Weigh the strip in grams. Cut a 1 inch strip of wood a foot from the end of the board.

Generally 135 F inside the wood is required for an hour or two. However you can also use this burner for many other. For woodworkers who decided to build a wood drying kiln.

How to build a low running cost dehumidifying wood drying kiln at home with no specialist equipment.

How I Built A Wood Kiln Out Of A 20 Shipping Container Steemit

Diy Wood Drying Kiln Woodarchivist

Drying Kiln Using A Reefer Body And Nyle Dehumidifier Woodweb S Sawing And Drying Forum

Homemade Wood Kiln Dehumidifier Hattie Wilson Blog

Drying 650 Bf Of Walnut In A Homemade Kiln R Woodworking

How To Build A Dehumidifier Wood Kiln Complete Process Youtube

Design And Operate A Small Scale Dehumidification Kiln Woodworking Blog Videos Plans How To

Diy Wood Drying Kiln Woodarchivist

How To Succeed At Air Drying Lumber Wood

Design And Operate A Small Scale Dehumidification Kiln Woodworking Blog Videos Plans How To

Drying Slabwood Temporary Dehumidification Kiln Life In The Log Yard Youtube

Typical Dehumidification Kiln Fpl 1999 P 12 10 Download Scientific Diagram

How To Properly Dry Live Edge Slabs Lancaster Live Edge

Design And Operate A Small Scale Dehumidification Kiln Woodworking Blog Videos Plans How To

Sauno Wood Drying Kilns By Logosol Wood Processing

Using A Small Scale Dehumidification Kiln

Front View Of The Dehumidification Dry Kiln Empty With Main Doors On Download Scientific Diagram